WASTE TO ENERGY

Wet waste, solid waste, and gaseous waste streams are potential high-impact

resources for the domestic production of biofuels, bioproduct precursors, heat,

and electricity. Wastes represent a significant and underutilized set of feedstocks

for renewable fuel and product generation.

These streams are available now without land-use change and in many cases

their utilization helps to address the unique and local challenges of disposing of

them. These resources are unlikely to diminish in volume soon, and as a result

(in the short and medium term), they represent a potentially low-cost set of

feedstocks that could help justify broader investment.

Energy companies are interested in converting waste-to-energy—specifically the

potential of the following waste streams:

- Commercial, institutional, and residential food wastes, particularly those currently disposed of in landfills;

- Biosolids, organic-rich aqueous streams, and sludges from municipal waste water-treatment processes;

- Manure slurries from concentrated livestock operations;

- Organic wastes from industrial operations, including but not limited to food and beverage manufacturing, biodiesel production, and integrated biorefineries, as well as other industries such as pulp and paper, forestproducts, and pharmaceuticals and

- Biogas derived from any of the above feedstock streams, including but not limited to landfill gas.

Beyond their interest in these traditional organic waste streams, energy

companies are interested in promoting novel, non-photosynthetic carbon-cycling

strategies that would support the valorization of inorganic carbon oxides, such as

carbon dioxide and carbon monoxide, found in industrial gaseous waste

emissions and biogas. In general, energy company’s efforts aim to improve

waste-stream management by closing waste loops and generating additional

value streams from waste.

Production Potential

In a 2017 report titled Biofuels and Bioproducts from Wet and Gaseous Waste

Streams: Challenges and Opportunities. The report found that the United States

has the potential to use 77 million dry tons of wet waste per year, which would

generate about 1.079 quadrillion British thermal units (Btu) of energy. Gaseous

feedstocks (which cannot be “dried” and therefore cannot be reported in dry tons)

and other feedstocks assessed in the report could produce an additional 1,260 trillion Btu of energy, bringing the total to more than 2.3 quadrillion Btu annually.

For perspective, in 2015 the United States’ total primary energy consumption

was about 97.7 quadrillion Btu.

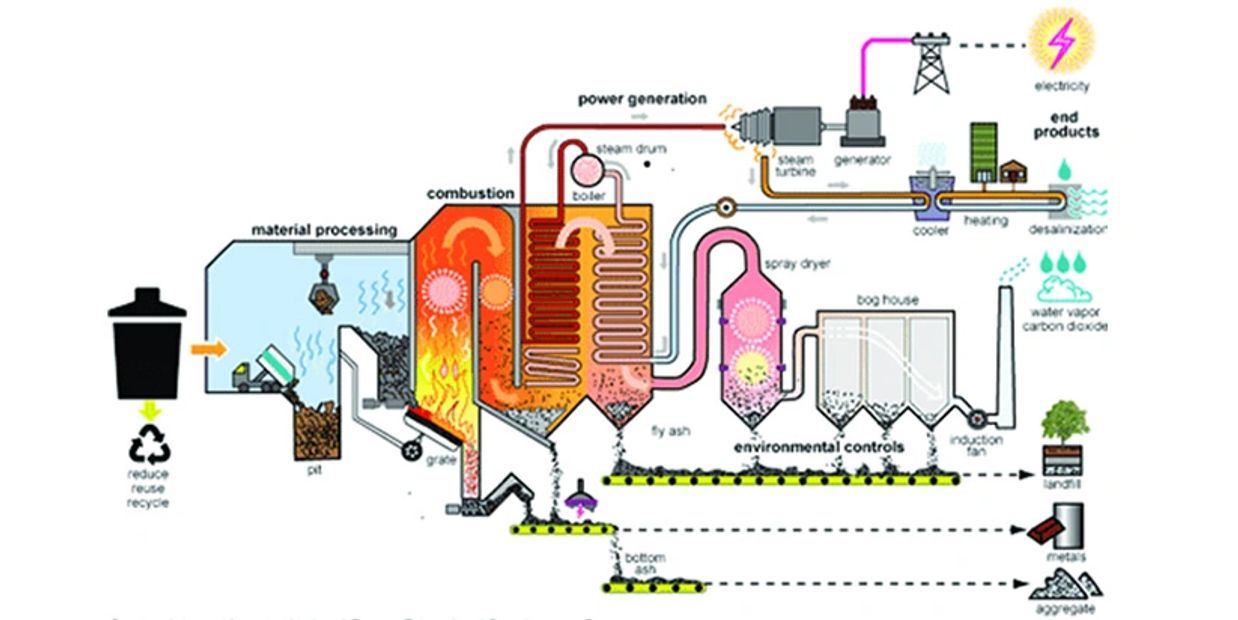

Conversion of Waste Streams

Wastes present a unique set of challenges in terms of conversion processes, and

energy companies have identified and are exploring several conversion

possibilities at a range of technology-readiness levels.

Hydrothermal Processing

One technology option energy company are considering is hydrothermal

processing. Research indicates that hydrothermal processing and related

technologies could process diverse blends of wet waste feedstocks, offering

potential for widespread deployment. Supercritical water also offers intriguing

options, as do other fluids at high temperature and pressure, such as carbon

dioxide.

Alternatives to Traditional Anaerobic Digestion

Anaerobic digestion (AD) has been widely deployed worldwide as a part of waste

treatment for sewage, animal manure, and other organic wastes. It produces

biogas, primarily comprised of carbon dioxide and methane, which can be

combusted to produce both heat and electricity. However, AD only reduces

waste volumes by roughly 50%, and the biogas requires substantial (and costly)

cleanup before it can be used as a vehicle fuel or injected into natural gas

pipelines. Also, it is capital-intensive, and therefore uneconomic at smaller

scales.

In addition to hydrothermal processing, which could conceivably replace AD,

energy companies are exploring several alternatives to traditional AD. AD is a

multi-step biological process. By arresting the final stage, it is possible to produce

higher-value precursors to bioproducts and liquid biofuels rather than biogas.

Alternative reactor designs, such as anaerobic membrane bioreactors, have the

potential to reduce capital costs dramatically, and possibly to produce biogas

with substantially more methane. There are also several promising possibilities to

use both the carbon dioxide and the methane from biogas to produce higher-

value fuels and products.

Waste-to-Energy Advantages.

Financially More effective: The expense of Waste-to-Energy depends on the technology as well as location as well as various other aspects.

Saves Natural Resources: Waste-to-Energy stays clear of the consumption of natural deposits like oil, gas, as well as coal which are or else used to create energy.

Better Use of Products: In Waste-to-Energy , metals left in the waste stream can be extracted from the deposit resulting from burning as well as the output can be reused.

Much Less Influence On Climate: Waste-to-Energy has a variety of ecological advantages. Waste-to-Energy generates much less greenhouse gas.

Produces Jobs: The Power Recuperation Council states that an ordinary Waste-to-Energy facility in the U.S. produces 58 full time tasks with at least 40 years of projected operation life.